Explanation

• The motion control system uses a progressive servo position control unit. High capacity user-friendly interface design ensures lossless communication with built-in perfect modular set device, automatic error detection function, self-diagnosis function.

• It has a 8.4″ color LCD high-resolution screen, just touch the screen and touch characters to view or enter data. It has user-friendly interface and shows various function settings, error report, working status.

• It is combined with a central control panel that allows the machine to easily recognize and operate all its features in the shortest training time.

• Saw feed is designed with Pivot-Arm type, then driven by AC servo motor and Ball screw.

• GFC loading system is driven by AC servo motor working together with ball screw, automatically compensating the backlash and also offering reliable precision of repeated positioning.

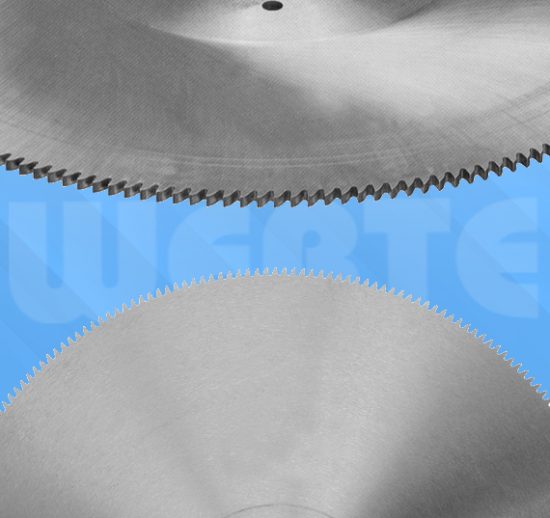

• It allows you to achieve low losses in cutting by connecting a thin TCT carbide tipped saw blade with a tooth thickness of up to 2 mm.

• Micro lubrication and cooling system works synchronously with cutting. It meets the dry and clean requirements of the working environment, reduces oil consumption, extends the life of the circular saw and reduces pollution.

• Faulty and correction cut parts are automatically thrown in separate directions and defect-free material is collected.