Production Processes for Special Disc Blades

First of all, laser cutting of the sheets in the desired dimensions is provided. The blades, which then turn into circular shapes, are subjected to heat treatment according to their type and the material to be cut. In the next stage, the products undergo surface grinding and from there, tip sharpening is carried out and they move on to the packaging stage.

Residues on the surfaces are removed and the grinding process is carried out to the wall thickness required by the customer.

Industrial knives used in the food industry (e.g. cutting canned vegetables or separating fish, meat and similar deep-frozen products) are produced from stainless steel for hygiene reasons; various meat knives, meat grinder knives, packaging line knives etc. for the food industry.

Since we only produce industrial knives upon order, the following information must be specified in case of product inquiry or order:

-Outer diameter of industrial blade

-Thickness of industrial blade

-Diameter of the shaft hole of the industrial knife

-Diameter, number and spacing of the fixing holes of the industrial blade, if any

-The material from which the industrial knife will be produced

-Type of cutting edge of industrial knife

-Cutting geometry of industrial knife

-The length of the cutting edge of the industrial knife

-The type of material that the industrial knife will cut

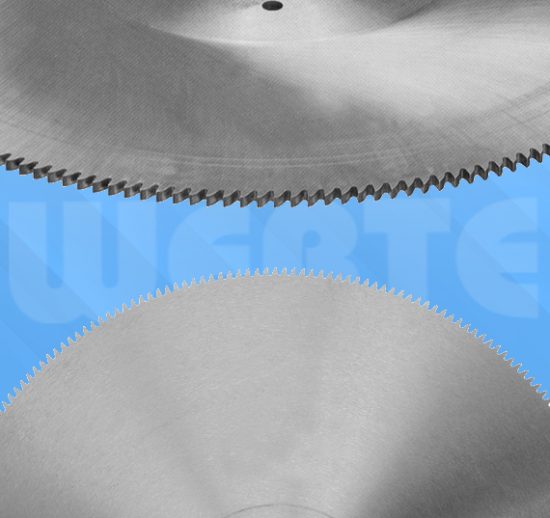

The blade of industrial knives is continuous in its basic version. If you wish, it is possible to produce teeth similar to the teeth of HSS circular saws that cut iron or special teeth for industrial blades. We can also produce industrial knives for you that do not have teeth on the blade but have grooves, thin lines or waves.

Some of the usage areas:

• Industrial knives for cutting rubber, industrial knives for cutting paper, industrial knives for cutting corrugated cardboard, industrial knives for cutting napkins and toilet paper, industrial knives for cutting fabric, industrial knives for cutting sponge, industrial knives for cutting metal sheets, industrial knives for cutting hydraulic hoses, industrial knives for cutting sandpaper. We manufacture knives, industrial knives for cutting fiber-rock wool, industrial knives for cutting insulation materials, industrial knives for cutting meat and food materials, industrial knives for cutting foil and industrial knives used in cutting packaging materials in general.

• The cutting edges of the produced knives vary depending on the materials cut. The rim bevel can be one-way, two-way or inward ground (cavity or linear ground). You can see the cutting tip types below.

| A. | Industrial knives with wide angle unidirectional blade bevel |

| B. | Industrial knives with narrow angle unidirectional blade bevel |

| C. | Industrial blades with one-way front-stage blade bevel |

| D | Industrial knives with wide angle bi-directional blade bevel |

| TO | Industrial knives with narrow angle and double-sided blade bevel |

| F | Industrial blades with front-stage bi-directional blade bevel |