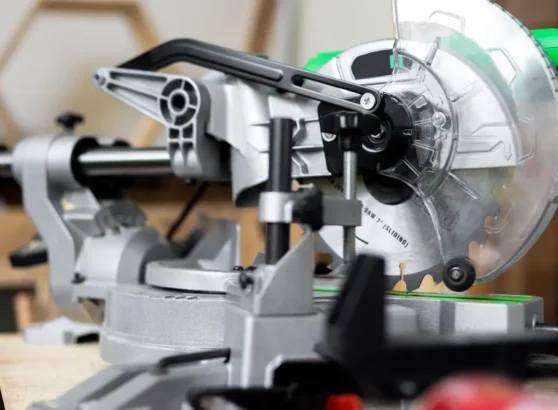

What is a Friction Saw?

Friction saw is used in cutting processes and is especially important in industrial applications.

It is a cutting tool that plays a role. Generally used for cutting hard and dense materials

This technology has a different working principle than traditional saw systems. Working Principle

Working Principle

The basic principle of the friction saw is that the teeth on the disk rotating at high speed are

It cuts by friction. This friction causes the material to heat up and cut

allows the process to be more effective. This feature is especially useful for demanding applications such as cutting metals.

provides advantages in transactions.

Usage areas

Friction saw is mainly used in industrial production, metalworking, automotive industry and so on

Used in areas. Especially for hard metals due to its high durability and cutting precision.

It is preferred in the processing of materials.

Role in Industrial Production

In industrial production processes, friction saws provide fast and precise cutting.

increases efficiency. With this feature, it is widely used in industrial facilities.

Advantages and Disadvantages;

Advantages:

– High Cutting Speed and Efficiency: The friction saw is fast thanks to the disk rotating at high speed.

cutting, which speeds up production processes.

– Effective Cutting of Hard Materials: Provides an effective cut in difficult materials such as hard metals.

– Low Vibration and Noise Levels: Lower vibration and noise levels than other cutting techniques

has noise levels.

Disadvantages:

– High Cost Equipment and Maintenance Requirement: Friction saw equipment is generally

It is costly and requires regular maintenance.

– Special Design Requirement for Certain Materials: Proper cutting properties for each material

There are special design requirements to achieve

Result: Innovative Solution in Cutting Technologies

The friction saw stands out as an important innovative solution in cutting technologies.

It plays a critical role in industrial sectors with its high performance and various advantages.

The cutting tool brings a number of advantages and challenges.

Increase in Industrial Efficiency:

In industrial production processes, the friction saw increases efficiency with its fast cutting features.

Fast and precise cuts improve workflow on the production line and support product variety.

Material Diversity and Compatibility:

The friction saw can effectively cut a wide range of materials, from hard metals to plastics.

has the ability to function in this way. This feature is used in different industrial applications.

increases usability.

Technological Challenges and Progress:

High cost equipment and special design requirements make the use of a friction saw

may be limited in some cases. However, with continuous technological advances, overcoming these challenges

and more efficient systems are likely to emerge.

Future Role:

The future role of the friction saw will become even more important in industrial production processes.

may come. With advances in materials science and engineering, this cutting technique has become more

can increase the ability to process a wider variety of materials and can be used more broadly in industrial sectors.

It may have a field of application.

In conclusion, the friction saw is an innovative and powerful solution in cutting technologies.

It has a critical role today and will evolve in the future with developments in industrial production processes.

may become even more important together.

werte As Cutting Technologies, we aim for the best in every cut. We strive to make everyone perfect with our excellent products and great after-sales support.