| Code No. | D | B. | D | Z. |

| PRF-200-01 | 200 | 2.0 | 32 | 124 |

| PRF-250-02 | 250 | 2.5 | 32 | 156 |

| PRF-300-01 | 300 | 2.5 | 32 | 186 |

| PRF-400-01 | 400 | 3.0 | 40 | 230 |

| PRF-400-02 | 400 | 4.0 | 40 | 230 |

| PRF-450-01 | 450 | 3.0 | 40 | 260 |

| PRF-450-02 | 450 | 4.0 | 40 | 260 |

| PRF-520-01 | 520 | 3.0 | 40 | 300 |

| PRF-520-02 | 520 | 4.0 | 40 | 300 |

| PRF-600-01 | 600 | 4.0 | 40 | 300 |

| PRF-600-02 | 600 | 5.0 | 40 | 240-280-300 |

| PRF-700-01 | 700 | 5.0 | 40 | 280-328-350 |

| PRF-700-02 | 700 | 6.0 | 40 | 280-328-350 |

| PRF-800-01 | 800 | 5.0 | 40 | 320-372-400 |

| PRF-800-02 | 800 | 6.0 | 40 | 320-372-400 |

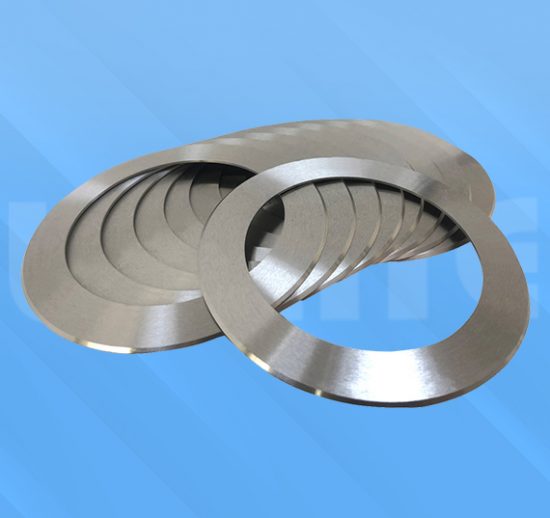

Application Areas of Friction Saws

– Steel pipes, profiles, angles, rails, billets, slabs and structural sections.

– Large and medium diameter cold cutting blades are generally used for cold cutting of carbon and alloy steels in multiple parts, below 250°C.

– Since the tooth pitches on the blade are short, friction heat occurs during cutting. For this reason, pressurized cooling application is also necessary for cleaning the teeth.

– Large and medium diameter hot cutting blades are designed for cutting above 750°C. The difference is that the tooth pitch is longer.